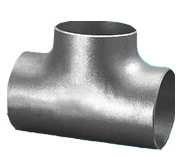

Tee

|

||

A tee is also called triplet,three way and "T" pieces and it can be used to either combine or split a fluid flow. Most common are tees with the same inlet and outlet sizes, but 'reducing' tees are available as well. it means the one or two ends are differ in dimension.due to thisdimension differ,the makes the tee fittings with the capacity to control the volume when requried |

|

|

Ref: TC01 |

||

Name: stright carbon steel tee fittings |

||

Pattern |

Weld |

Seamless |

Nominal size |

1/2”-48” (DN15-DN1200) |

1/2”-20” (DN15-DN500) |

Wall thickness |

2~100mm |

2~50mm |

Bend radius |

SCH5S-SCH160 ,XXS |

SCH5-SCH160 |

Type |

Tee/reducing tee |

Tee/reducing tee |

| Material | ||

|---|---|---|

| Carbon | SA234 WPB, SA234 WPC,SA42 WPL6, SA42 WPL3, WP1. MSS-SP75 WPHY,WPHY 46,WPHY 52,WPHY 56,WPHY 60,WPHY 65, WPHY 70 DIN 1629 St37, RST37.2 St52 |

|

| Other types | ||

| Fittings |

|

|

| Standards | ||

| ASTM | ASME/ANSI B16.9 Factory-Made wrought steel pipe fittings |

|

| JIS | JIS B 2302:1998Screwed type steel pipe fittings JIS B2311 Universal steel butt-welding pipe fittings JIS B2312 Steel butt-welding pipe fittings JIS B2313 Steel plate butt-welding pipe fittings JIS B 2321:1995Aluminum and Aluminum alloy butt-welding pipe fittings |

|

| EURO |

|

|

| Application | For industry fields use,such as petroleum, power, papermaking, chemical, aviation, boiler heat, exchanger fields. For electric, shipbuilding, construction fileds For the foodstuff,medical equipment, and other fields |

|

| Further treatment | ||

| Surface galvanized,antirust coating Epoxy & FBE Coating Electro Polishing |

||